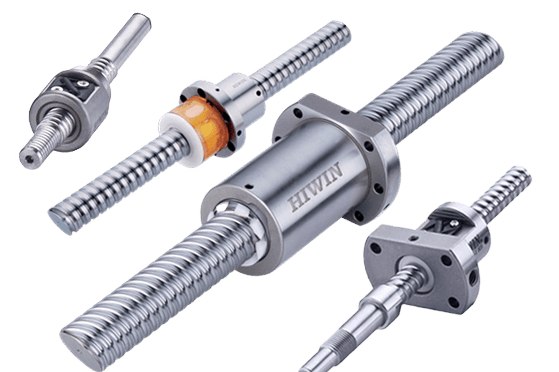

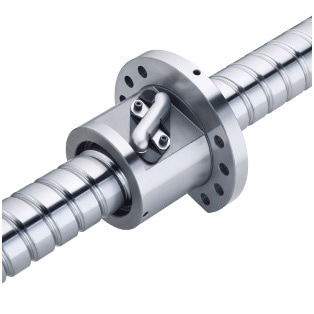

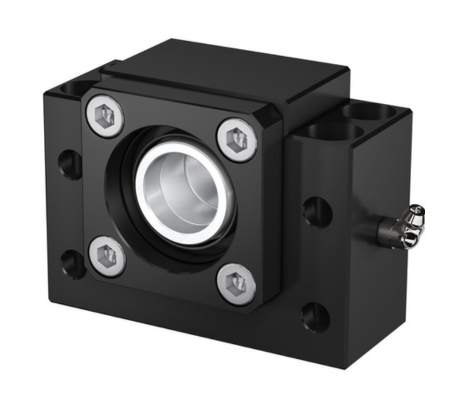

Precision Ground Ballscrew

Hiwin precision ballscrews are manufactured through a grinding process of the screw spindle. Precision ground ballscrews offer high positioning accuracy, excellent repeatability, smooth movement, and a long service life. These highly efficient ballscrews are the ideal solution for a wide range of applications.