Precision Ground Ballscrew Series

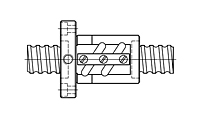

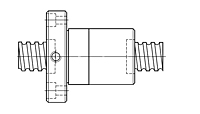

FSV Type Nuts (97)

Flange end, single nut, tube above the nut diameter.

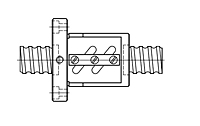

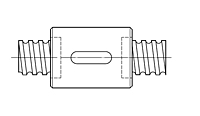

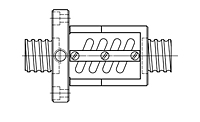

FSW Type Nuts (104)

Flange end, single nut, tube within the nut diameter.

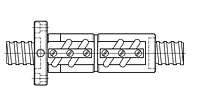

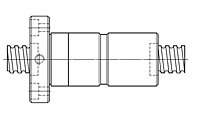

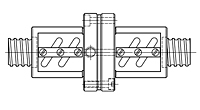

FDV Type Nuts (95)

Flange end, double nut, tube above the nut diameter.

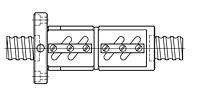

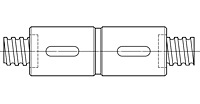

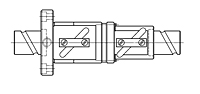

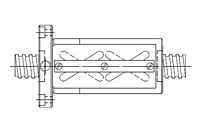

FDW Type Nuts (111)

Flange end, double nut, tube within the nut diameter.

FSI Type Nuts (83)

Flange end, single nut, internal recirculation cap.

RSI Type Nuts (61)

Round, single nut, internal recirculation cap.

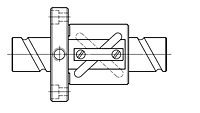

FDI Type Nuts (72)

Flange end, double nut, internal recirculation cap.

RDI Type Nuts (61)

Round, double nut, internal recirculation cap.

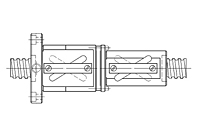

PFDW Type 1 Nuts (42)

Flange to flange, double nut, tube within the nut diameter.

PFDW Type 2 Nuts (12)

Large lead, flange end, compression preload, double nut, tube within nut diameter.

PFDW Type Nuts (13)

Large lead, flange end, compression preload, double nut, tube within nut diameter, double start.

PFDI Type Nuts (52)

Flange to flange, double nut, internal recirculation cap.

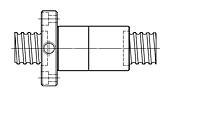

OFSW Type Nuts (61)

Offset pitch preload, flange end, single nut, tube within the nut diameter.

OFSW Type 2 Nuts (14)

Offset pitch preload, flange end, single nut, tube within the nut diameter.

OFSI Type Nuts (32)

Offset pitch preload, flange end, single nut, internal recirculation cap.

DFSV Type Nuts (5)

Double start, flange type mounting, single nut, circulation tube above the nut diameter.

DFSH Type Nuts (17)

High lead double start, flange type mounting, single nut, with end cap design.

.jpg)

QFSH Type Nuts (13)

High lead quad start, flange type mounting, single nut, with end cap design.

FSC Type Nuts (357)

Flange type mounting, single nut. Super S series for low noise and space-saving design, Dm-N value of up to 220,000, high acceleration/deceleration.

FDC Type Nuts (357)

Flange type mounting, double nut, Super S series for low noise and space-saving design, Dm-N value of up to 220,000, high acceleration/deceleration.

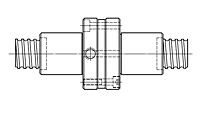

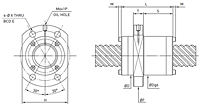

R1 Rotating Nuts (5)

Application:

Semi-conductor industries, Robots, Wood machines, Laser cutting machines, Transporting equipment.

- 1. Compact and high positioning: It is a compact design using nut and support bearing as an integral uint. 45-degree steel ball contact angle make a better axial load. Zero backlash and higher stiffness construction give a high positioning.

- 2. Simple installation: It is installed simply by fixing the nut on the housing with bolts.

- 3. Rapid feed: No inertial effect produced by the integral unit rotating and the shaft fixed. Can select smaller power to meet the rapid feed requirement.

- 4. Stiffness: Have a higher trust and moment stiffness, because the integral unit have an angular contact construction. There is no backlash while rolling.

- 5. Quietness: Special end cap design allows steel balls circulating inside the nut. Noise generated by high speed operation lower than ordinary ballscrew.